Pengrui Rock Drilling Technology——"The ultimate force to penetrate every rock wall"

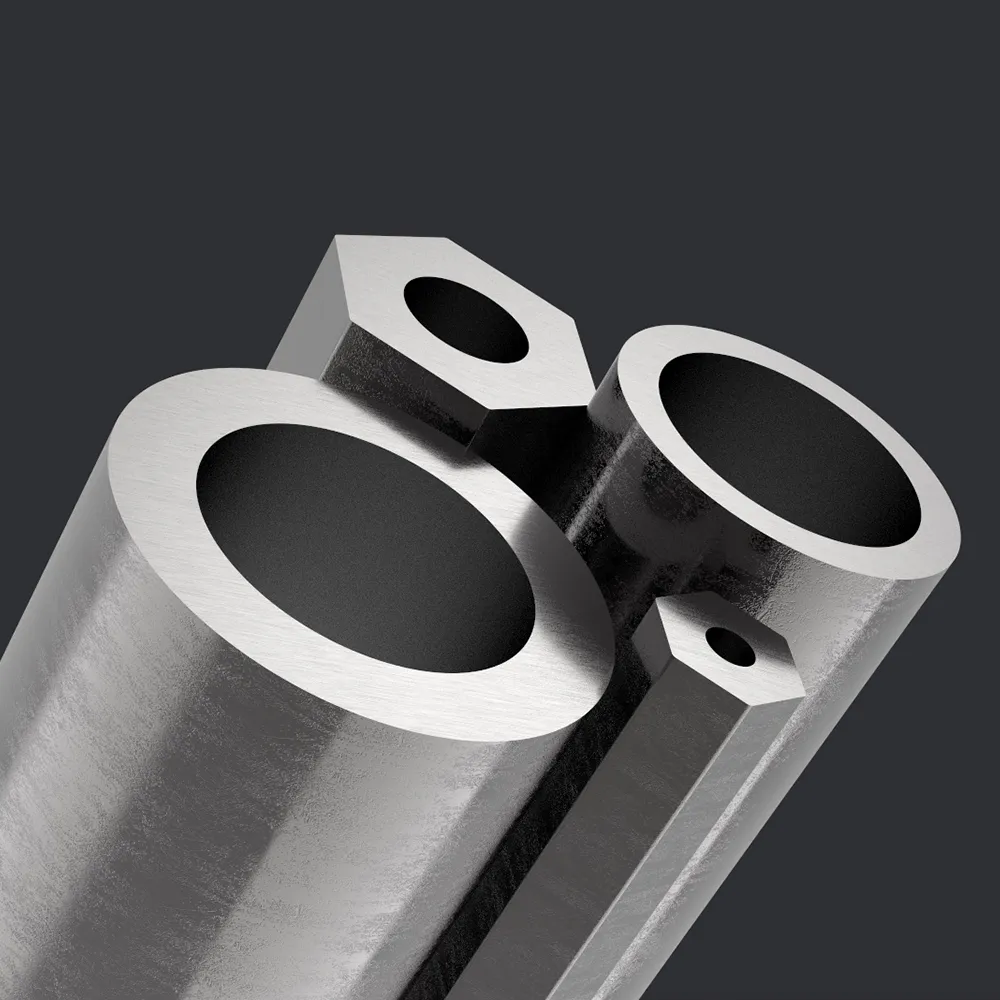

Hollow steel for top-hammer drilling

Core products

Hollow steel for top-hammer drilling - breaking through the limits of rock penetration

Key properties: Fatigue strength | Wear resistance | Toughness

Technical support: Strict quality control system | Comprehensive intelligent process | Professional R&D support

Advantages

(1) Intelligent process for precise empowerment

The comprehensive intelligent processing technology is employed to precisely regulate the straightness and inner hole eccentricity, ensuring the efficient interaction between the drilling tool and the drilling rig, thereby reducing energy loss and enhancing drilling efficiency.

(2) Exceptional performance, durability and reliability

The design of the alloy composition has been optimized, resulting in a product that possesses both high strength and high toughness. This enables it to adapt effectively to complex geological environments and extend its service life.

Category:

Hollow steel for top-hammer drilling

Product Specification

Cross-sectional shapes | Application | Characteristics |

| rounded | Surface mining (open pit drilling trucks, etc.) | Excellent strength and toughness |

| hexagonal | Underground excavation (hydraulic rock drills, etc.) | Higher torque transmission capacity for high torque drilling operations |

Common production specifications

| Round - Hollow steel for rock drilling | Hexagonal - Hollow Steel for Rock Drilling |

| R32 | H19 |

| R36 | H22 |

| R39 | H25 |

| R46 | H28 |

| R52 | H32 |

| R56 | H35 |

| R60 | H38 |

| R65 | |

| R76 | |

| R87 | |

| Customized production with production tolerances provided by the customer | |

Product Material

| Material-Grade | Chemical Composition% | Description | Application | Industrias | Field of application |

| 23CrNi3MoA | C:0.23 Si:0.30 Mn:0.68 P:0.010 S:0.005 Cr:1.3 Ni:2.9 Mo:0.2 | Air-hardening high-nickel alloy steel; Excellent carburizing responsiveness; High fatigue strength and wear resistance after case hardening; Core retains high toughness. | Suitable for shanks Tapered rods Extension rods | Geological Exploration Infrastructure Mining Tunneling | Rock drilling tools and heavy machinery components for high wear and impact environments. |

| 40SiMnCrNiMo | C:0.40 Si:1.40 Mn:0.95 P:0.008 S:0.004 Cr:0.75 Ni:0.48 Mo:0.2 | High strength silicon-alloyed structural steel; Outstanding overall strength, toughness and fatigue resistance; Suitable for high frequency impact and alternating loads. | Guide rods Tapered rods Integral rock drilling steel | Mining Tunneling Geological Exploration Infrastructure | Suitable for rock drilling tools, key structural components of construction machinery and mining equipment under high-impact and high-load environments. |

| 25Cr3MoA | C :0.25 Si :0.30 Mn :0.55 P :0.020 S :0.015 Cr: 3.20 Ni : - Mo:0.50 | Air-hardenable chromium-molybdenum alloy steel; Excellent surface induction hardening adaptability; Good carburizing properties; High fatigue strength and wear resistance after surface hardening. | Shank Rods Tapered rods Extension Rods | Geological Exploration Mining Tunneling Infrastructure | Drill systems and accessories for high impact, high abrasion and alternating load scenarios. |

Technical Support & Services

| Project | Description |

| Customized Solutions | One-stop service from design, manufacturing to after-sales to accurately match the needs. |

| Professional Technical Support | A technical team with 20 years of experience provides real-time consultation and on-site support. |

| International Certification Guarantee | Penray has been certified with ISO 9001:2015 Quality Management, ISO 14001:2015 Environmental Management and ISO 45001:2018 Occupational Health and Safety Management System, demonstrating our commitment to high standards of quality, sustainability and employee health and safety protection. |

| Business Consulting | Email:【pengrui@chinapengrui.com】【JaydenYin@chinapengrui.com】 |

Keywords:

Hollow steel for top-hammer drilling