Pengrui Rock Drill Steel——Breaking Through the Limits of Rock Penetration

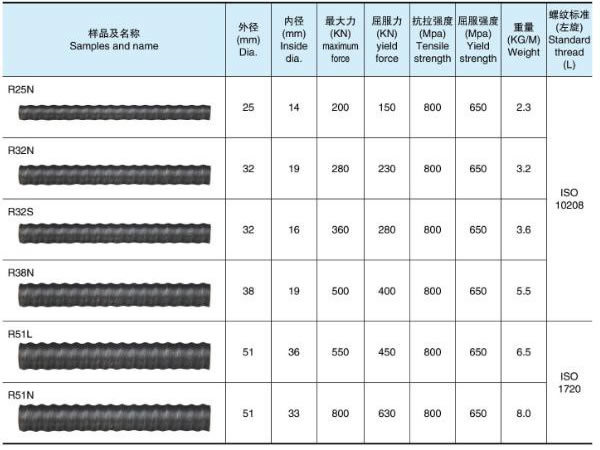

Hollow grouting rock bolt

The finished drill rods are mostly used for relatively stable and complete rock strata. Anchoring agents such as resin, engineering glue and quick-setting cement are injected from the center of the rock bolt, which has better anchoring quality than ordinary rock bolts.

Category:

Hollow Grouting Anchor Rods

Raw materials for hollow grouting rock bolt

The finished drill rods are mostly used for relatively stable and complete rock strata. Anchoring agents such as resin, engineering glue and quick-setting cement are injected from the center of the rock bolt, which has better anchoring quality than ordinary rock bolts. Due to the emergence of self-drilling hollow grouting rock bolt, hollow grouting rock bolts can also be used in strata under loose rock and soil conditions. The rock bolt body of the hollow rock bolt features a hollow design, utilizing the central hole of the rock bolt body as a conduit for high-pressure air and water during drilling, as well as a grouting channel. In comparison to the solid rock bolt body, the hollow rock bolt body design offers enhanced rigidity and shear strength. The outer surface of the rock bolt body is a full-length standard large-pitch threaded structure, which facilitates the cutting and lengthening of the rock bolt. In comparison to a smooth rock bolt body, this design increases the bonding area between the rock bolt body and the grouting material, thereby enhancing the anchoring force.

The hollow rock bolt, in comparison to the solid rock bolt body, features a design that offers enhanced rigidity and shear strength. The outer surface of the rock bolt body is a full-length standard large-pitch threaded structure, which facilitates the cutting and lengthening of the rock bolt. In comparison to a smooth rock bolt body, this design increases the bonding area between the rock bolt body and the grouting material, thereby enhancing the anchoring force. Pressure grouting of the rock bolt through the hollow rock bolt body serves to consolidate fractured rock masses, isolate groundwater, and prevent corrosion of the rock bolt body. This process rapidly establishes supporting force and ensures the stability of the surrounding rock.