Pengrui Rock Drill Steel——Breaking Through the Limits of Rock Penetration

Rock Drill Steel

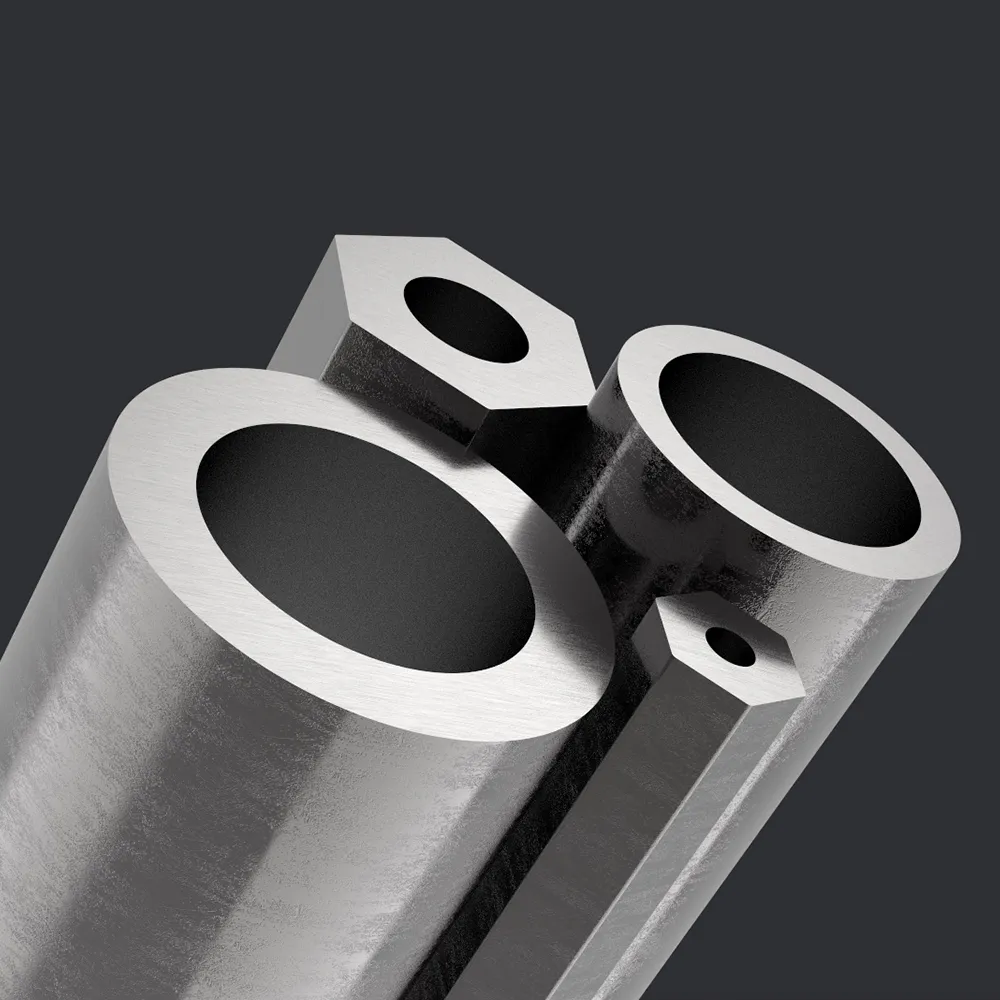

Core Product

Developed for the manufacturing of top-hammer rock drill rods

Key Performance

| Fatigue Resistance |

| Wear Resistance |

| Toughness |

Technical Assurance

| Full Process Intelligent Manufacturing |

| Rigorous Quality Control System |

| Professional R&D Support |

Competitiveness

| Intelligent Processes, Precise Empowerment |

| Outstanding Performance & Reliability |

Category:

Rock Drill Steel for Top-Hammer

Competitive Advantages

-Utilizing full-process intelligent manufacturing technology, we precisely control straightness and internal bore eccentricity, ensuring efficient coordination between drilling tools and drilling rigs, reducing energy loss, and enhancing rock drilling efficiency.

-With optimized alloy composition, our products combine high strength and toughness, adapt to complex geological conditions, and offer extended life cycle.

Product Specification

Cross-section Shape | Application Field | Characteristics |

| Rounded | Surface Mining (e.g., open-pit drilling rigs) | Combines excellent strength and toughness |

| Hexagonal | Underground Excavation (e.g., hydraulic rock drilling rigs) | Provides higher torque transmission capability, meeting high-torque drilling operation demands |

Common production specifications

| Round - Hollow steel for rock drilling | Hexagonal - Hollow Steel for Rock Drilling |

| R32 | H19 |

| R36 | H22 |

| R39 | H25 |

| R46 | H28 |

| R52 | H32 |

| R56 | H35 |

| R60 | H38 |

| R65 | |

| R76 | |

| R87 | |

| Customized production with production tolerances provided by the customer | |

Product Material

Material-Grade | Chemical Composition% | Description | Application | Industrias | Field of application |

23CrNi3MoA | C:0.23 | High-nickel alloy steel with air-hardening properties; excellent carburizing response; after surface hardening, exhibits high fatigue strength and wear resistance; core remains highly tough. | Shankrods,Tapered rods, Extension rods | Geological exploration, Infrastructure, Mining, Tunnel construction | Suitable for rock drilling tools and heavy machinery components in high-wear and high-impact environments |

40SiMnCrNiMo | C:0.40 | High-strength silicon alloy structural steel; excellent overall strength, toughness, and fatigue resistance; suitable for high-frequency impacts and alternating loads. | Politrods, Tapered rods, Integrated rock drilling steel | Tunnel Construction, Geological Exploration, Infrastructure | Suitable for rock drilling tools, key components of engineering machinery, and mining equipment parts in high-impact, high-load environments |

25Cr3MoA | C:0.25 Si:0.30 Mn:0.55 P:0.020 S:0.015 Cr:3.20 Ni:- Mo:0.50 | Air-hardened chromium-molybdenum alloy steel; excellent surface induction hardenability; good carburizing properties; exhibits high fatigue strength and wear resistance after surface hardening. | Shankrods,Tapered rods, Extension rods | Mining, Tunnel Construction, Geological Exploration, Infrastructure | Suitable for rock drilling chisel systems and other accessories in environments with high impact, severe wear, and alternating loads. |

Technical Support & Services

Item | Description |

| Customized Solutions | One-stop service from design, manufacturing to after-sales support, precisely meeting your requirements. |

| Professional Technical Support | A technical team with 20 years of experience, offering real-time consultation and on-site support. |

| International Certification Assurance | ISO 9001:2015 for Quality Management System ISO 14001:2015 for Environmental Management System ISO 45001:2018 for Occupational Health and Safety Management System |